{"product":{"productId":"agid.22634","price":14.06,"name":"Cam levers, aluminium with steel mandrel collet and plastic thrust washer"},"currency":"EUR"}

Material

Handles, cast aluminium, EN AC-46200.

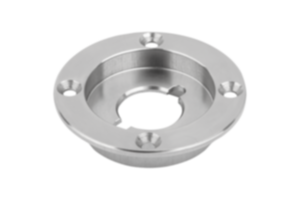

Thrust washer, fibreglass reinforced PA 66 GF 35 X plastic.

Hinge pin stainless steel.

Tie rod, washer, collet, disc spring, steel.

Thrust washer, fibreglass reinforced PA 66 GF 35 X plastic.

Hinge pin stainless steel.

Tie rod, washer, collet, disc spring, steel.

Version

Grips fine structure powder-coated, black or red RAL 3003.

Thrust washer, black.

Washer blue-passivated.

Tie rod and collet black oxidised.

Thrust washer, black.

Washer blue-passivated.

Tie rod and collet black oxidised.

Exibir mais

Exibir menos

Descrição

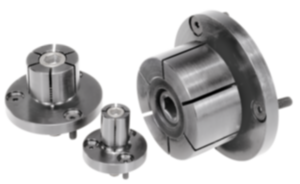

Product description

With this patented clamping system, two components can be positioned without tools via form fit and then clamped together by frictional connection. The clamping range and the holding force is adjustable.

Material

Handles, cast aluminium, EN AC-46200.

Thrust washer, fibreglass reinforced PA 66 GF 35 X plastic.

Hinge pin stainless steel.

Tie rod, washer, collet, disc spring, steel.

Thrust washer, fibreglass reinforced PA 66 GF 35 X plastic.

Hinge pin stainless steel.

Tie rod, washer, collet, disc spring, steel.

Version

Grips fine structure powder-coated, black or red RAL 3003.

Thrust washer, black.

Washer blue-passivated.

Tie rod and collet black oxidised.

Thrust washer, black.

Washer blue-passivated.

Tie rod and collet black oxidised.

Note

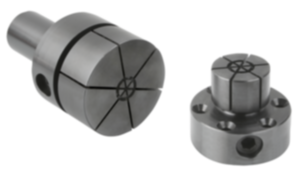

It is recommended that the cam lever is in a vertical position when the collet is positioned in the bore.

The function of the clamping system was tested in bores with tolerance H7. All values for retaining force are guide values and are given without safety factor.

The suitability for the respective application must be checked by the user.

The function of the clamping system was tested in bores with tolerance H7. All values for retaining force are guide values and are given without safety factor.

The suitability for the respective application must be checked by the user.

Advantages

Se pueden unir dos componentes sin necesidad de herramientas. Los componentes están centrados de forma óptima cuando están tensos. Debido a la forma compacta, el mandril de sujeción con palanca excéntrica también se puede instalar en perforaciones ciegas. Las perforaciones no están sujetas a ningún requisito especial de dimensión. La superficie y la forma tampoco requieren características especiales.

Principio de función

El sistema de sujeción se introduce en estado abierto en la perforación. Para iniciar el proceso de cierre, se abre el mandril de sujeción y se tensa en el componente inferior. El paquete integrado de muelles de disco genera un efecto de tracción hacia abajo que prensa entre sí los dos componentes al final del proceso de cierre.

Indicación sobre el dibujo

1) acionada

2) não acionada

2) não acionada

Observação importante sobre o download de modelos CAD

Para fazer o download de nossos modelos CAD, você deve primeiro fazer o login. Se ainda não tiver criado uma conta, registre-se em "Minha conta" (lado direito da tela) e siga as instruções.